Electroless Nickel PlatingElectroless nickel plating (ENP) is an advanced process that applies a nickel-alloy layer through chemical reduction, eliminating the need for electrical current. This innovative technique is widely adopted across engineering industries, utilizing nickel-phosphorus alloys with phosphorus content ranging from 2% to 14%. |

|

|

Key Benefits of Electroless Nickel PlatingElectroless nickel plating offers numerous advantages that make it a preferred choice for diverse applications: • Superior Corrosion Resistance: high-phosphorus ENP (10-14%) forms an amorphous structure, delivering excellent resistance against corrosion caused by elements like saltwater, carbon dioxide and hydrogen sulphide; • Uniform Coating Thickness: ENP ensures consistent coating thickness across complex surfaces, including internal cavities, threads and tubing, outperforming traditional electroplating methods; • Exceptional Hardness and Wear Resistance: even without heat treatment, ENP demonstrates remarkable hardness and durability, making it ideal for high-wear environments; • Cost Efficiency: ENP provides a cost-effective alternative to corrosion-resistant alloys, particularly for applications vulnerable to localized corrosion, such as weld joints and flanges.

Customizing ENP for Specific ApplicationsThe performance of ENP can be tailored by adjusting the phosphorus content. High-phosphorus coatings offer better corrosion resistance, while lower phosphorus levels enhance surface hardness. Prime Hyd’s technical team ensures the optimal phosphorus concentration is selected to meet your project’s exact requirements.

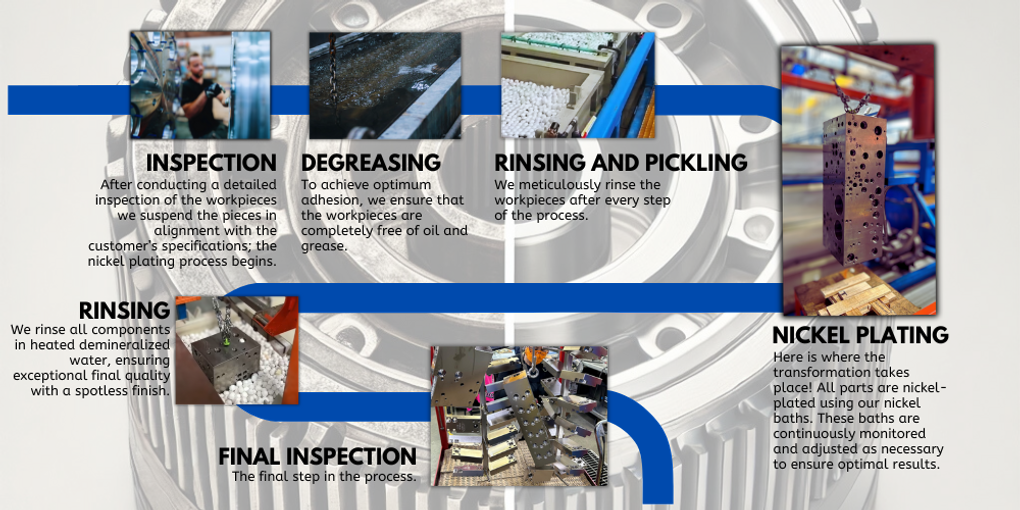

Achieving High-Quality ENP ResultsEnsuring the success of an ENP coating requires meticulous attention to: • Surface Preparation: properly prepared surfaces are essential for optimal adhesion. Irregularities like burrs or corrosion must be removed; • Cleaning: a thoroughly cleaned substrate free of oils, dirt, and residues ensures a smooth coating process; • Bath Control: precise monitoring of bath conditions, including temperature, pH, and chemical concentrations, is critical for consistent results.

Why Choose PrimeHyd for ENP Services?At PrimeHyd, we combine expertise and precision to deliver superior electroless nickel plating solutions. Our process includes: • Advanced surface inspection techniques; • Use of certified ENP chemicals and demineralized water; • Bath filtration, air agitation and chemistry monitoring; • Rigorous inspection protocols to ensure flawless results.

Treated MaterialsElectroless nickel can be applied over a variety of materials. PrimeHyd process is suitable for the following alloys: • Cast Irons • Carbon Steel

Partner with Prime Hyd for reliable, high-quality electroless nickel plating tailored to your needs.Contact us today to discuss your project and discover how ENP can improve your products' performance and lifespan. |